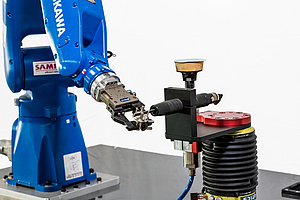

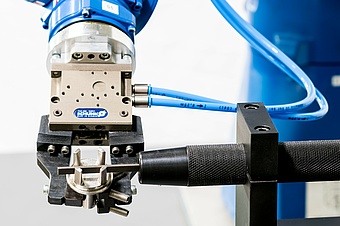

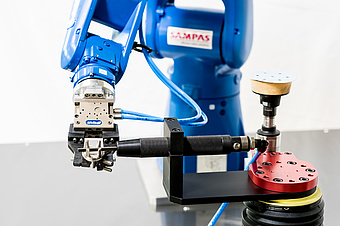

Stroke filing processes

The process is particularly suitable for removing separating edges / particles on die-cast aluminium parts. Automated deburring can be performed with either the component or tool acting as a guide.

Your advantages:

- High tolerance to

- Contact pressure

- Contour variations in the component

- Position accuracy of the robot

- Processing speeds

- Cycle time optimised movements are possible, since up-cut / synchronous movements need not be considered unlike in milling

- Tracking accuracy good processing of corners and sharp edges

- Safe tool changes without risk of injury

- No harmful vibrations due to automated equipment

Technical details:

| File drive | pneumatic and electrical |

| Applications | stationary or robot guided |

| Suitable processing material | steel, cast steel, cast iron, non-ferrous metals |

| Stroke lengths | 2 - 10 mm |

| Processing speeds | up to 300 mm / sec |

Our services:

- Project planning and project management

- Robot PLC and visualisation

- Programming

- Construction (electrical and mechanical)

- Commissioning

- Interfaces in production

- Manufacturing and assembly